Our team is your team

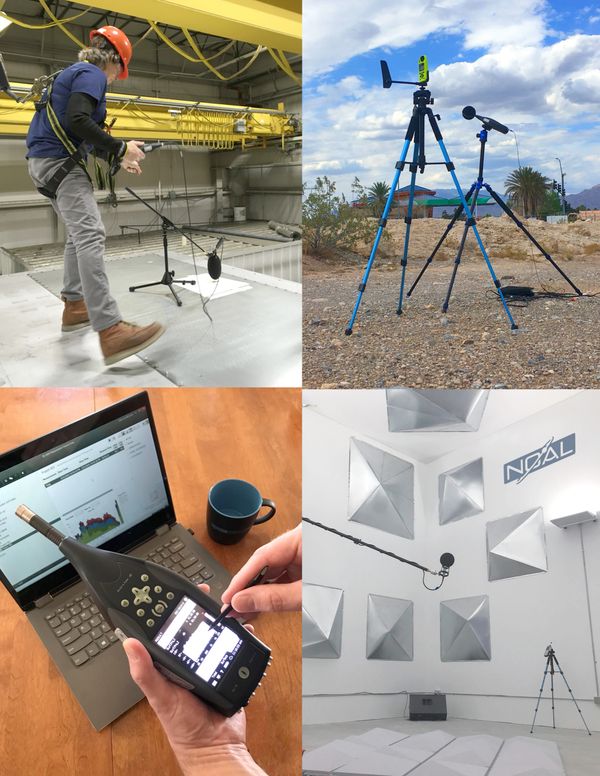

The North Orbit team brings decades of experience and a real passion for the field of acoustics to every project. Our owners are also the primary techs performing the testing with rare thoroughness and attention to detail.

Take advantage of the in-depth consults and testing only an owner-operated acoustic lab can offer. Not only hard data on sound-based questions from seasoned experts but input on the tests and personal analysis of the results.

Associations and memberships

STAFF PUBLICATIONS AND PRESENTATIONS

David M. Berg, Benjamin M. Shafer, and Elliott B. Dick, "Challenges testing high transmission-loss walls in a laboratory", Noise-Con 2022, Lexington, Kentucky.

Elliott B. Dick, "Review of concepts relating to measurement quality", Noise-Con 2022, Lexington, Kentucky.

Elliott B. Dick, Samantha Rawlings, Benjamin M. Shafer, and Matthew Golden, "Streamlining ASTM acoustical standards", 182nd Meeting of the Acoustical Society of America, Denver, Colorado, 2022.

Elliott Dick, Tim Casey, May Raad, and Christopher Nachtsheim. Precision and Bias Statements for AASHTO Standard Methods of Test TP 98 and TP 99. Contractor’s Final Report for NCHRP Project 10-88, Transportation Research Board of the National Academies of Sciences, Engineering, and Medicine. 2015. Available from http://www.trb.org/Main/Blurbs/173562.aspx.

Elliott B. Dick, David M. Berg, "Simulating the variance of Sound Transmission Class ratings from real measurement parameters", Noise-Con 2013, Denver, Colorado, 2013.

Elliott B. Dick, "Using large database management systems for noise analyses", INTER-NOISE 2012, New York City, NY, 2012.

Elliott B. Dick, Wilde, James, "Rehabilitated PCC Surface Characteristics", TERRA Innovation Series: MnROAD Research Conference, Minneapolis, MN, 2011.

Elliot B. Dick, Tim Casey, and Bernard Izevbekhai. Influence of Pavement on Traffic Noise: Statistical Pass-by Measurements of Traffic on Several Interstate Pavements. No. MN/RC 2010-40. Minnesota Department of Transportation, Research Services Section, 2010. Available from: http://www.lrrb.org/pdf/201040.pdf.

Elliott B. Dick, Gina Jarta, Kent A. Peterson, "The 2010 FGI Acoustical Guidelines for Healthcare Facilities", AIA Minnesota Convention, Minneapolis, Minnesota, 2010.

Elliott B. Dick, David M. Berg, Derrick Knight, "Building Sound Isolation Performance Regulation and Testing", Institute of Building Officials Conference, 2007.

If you would like North Orbit to present at your acoustic-related event, please contact us.

NORTH ORBIT NEWS

North Orbit Acoustic Laboratories Achieves Brag-Worthy Flanking Limit

Inside a nondescript warehouse in the shadow of the Minnesota State Capitol, the team at North Orbit Acoustic Laboratories quietly made some very loud noise. When testing their new acoustic laboratory’s flanking limit, they discovered they had one of the highest on the continent.

A flanking limit is a lab’s capacity to measure sound. If you are a baker, for instance, and have a two-cup measure, you can measure a cup and a half or two cups of water, but you can’t measure more than that. With a bigger, four-cup measure you can measure two and a half cups and beyond, all the way to your cup limit. The same is true with sound. If your flanking limit is low, and your lab can only “hold” a small amount of sound, you are limited in what you can measure. But if your lab can handle high decibel levels, like North Orbit, you expand your ability to measure.

North Orbit uses a two-room reverberation chamber to test the change in sound levels as sound waves travel through different materials. This type of test, referred to as Sound Transmission Loss or STL, expresses in decibels the difference in sound levels for all of the frequencies recorded. A single-number STC rating (Sound Transmission Class) is dervied from the STL and is the most commonly used expression of sound isolation. A typical drywall and stud assembly might achieve a 45 STC, a more robust wall might earn a 62. For special situations, like theater walls or industrial isolation, a wall might need to achieve an 82 or above. North Orbit’s remarkable flanking limit of 89 allows them to measure them all.

In order to find their flanking limit, the team at North Orbit created over 120 decibels of sound in the chamber’s source room then measured the transmission loss through a test specimen into the receive room. At the point that sound escapes the chamber through a path that is not intended, you have found your flanking limit. The chamber construction performs so well that the limit they achieved is bounded more by their ability to make a sound loud enough (they are already at nearly jet-engine levels) than by what the chamber can hold.

This news will be of particular interest to manufacturers and engineers who use highly rated sound walls in their industrial or military settings. In mixed-use structures, architects or designers might need to specify high STC values where one tenant requires quiet and a neighboring tenant does not (imagine a workout facility next to a therapist). Highly rated walls are also used in high-performance theaters or where industrial sound isolation is required.

The design and construction of the reverberation chambers at North Orbit’s St. Paul location was an in-house accomplishment. Elliott Dick, North Orbit Acoustical Scientist, says, “I don’t feel like I can separate my role from the team because there was so much give-and-take in developing the chamber design and the specimen opening. It was all of us working together, trying to figure out what is buildable and what will achieve our needs.”.

“It’s an advantage to have so many highly skilled staff members on a project like this. We didn’t have to go outside for the expertise. Achieving this very high flanking limit, and actually, the construction of the whole lab, has been a passion project for our whole crew,” said North Orbit President Dave Berg. With this feather firmly in their cap, the crew at North Orbit will turn their capable attention to designing and building a hemi-anechoic chamber on site. North Orbit is an A2LA accredited acoustic laboratory with facilities in St. Paul, MN, and Dyersville, IA.

Let us know about your testing goals - maybe we can help.

917 Rice Street, Saint Paul, MN 55117 info@northorbit.com

Copyright © 2026 North Orbit Acoustic Laboratories - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.